Structured Project Delivery, Backed by Precision and Visibility

At Metal Assemblies, we follow a structured four-phase project management system that enables us to guide new projects from contract review through to launch performance review with efficiency and precision. Each key milestone is carefully reviewed and approved by the senior management team before moving on to the next phase.

This approach ensures every stage of the project receives the attention it needs, with full visibility across the business through a clearly defined visual tracking system.

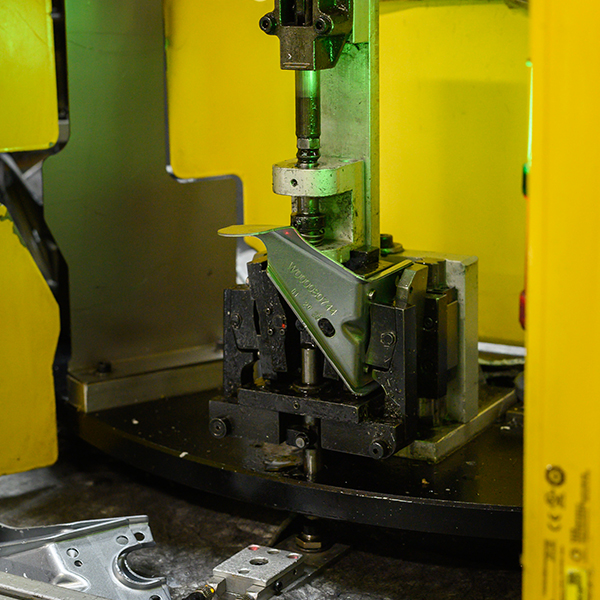

3D Printing for Faster Validation and Smarter Design Decisions

We use a Bamboo 3D printing machine to support early-stage design validation and part evaluation. It allows us to print both individual components and complete assemblies, which is particularly valuable in welding gun studies and assessing suitability before manufacture. This gives us a tangible preview of the component or assembly before production begins, helping to streamline the development process.

In addition, our ability to work with all formats of CAD data ensures we are fully equipped to meet the APQP requirements of our customers.

Industries and applications

We provide project management for the following industries, with careful consideration placed on the design and product requirements of that particular business.

Explore our other services

Contact Us

Talk to our team

Simply send us your queries and questions and a member of our

team will be in touch.

Visit us

If you would like to talk to us in person, you can find us at our manufacturing facility in West Bromwich, UK.