Delivering quality you can measure

Quality underpins every aspect of our operations, and we have made dedicated investments in our processes to ensure they meet the highest standards, from initial design through to final delivery.We apply the Poka Yoke methodology to proactively identify and prevent errors early in the production process. Operating in sectors where performance and safety are paramount, we recognise that every component, no matter how small, must meet exacting standards.

To consistently deliver quality, we utilise the following technologies:

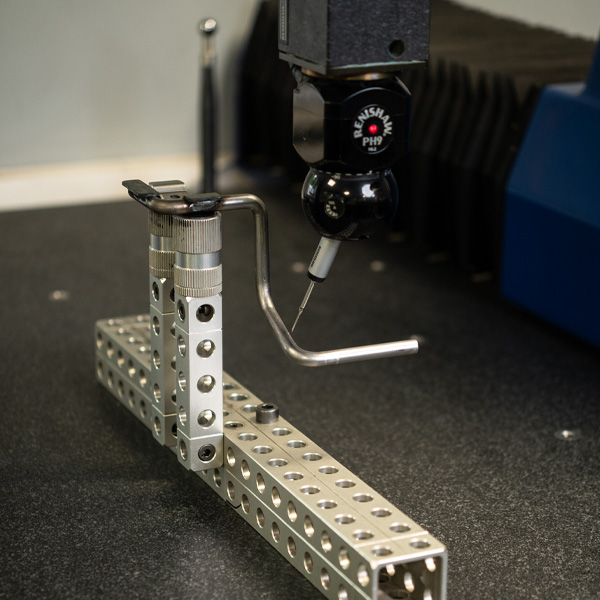

CMM

Our LK Metris coordinate measuring machine (CMM) allows us to assess our products against master CAD models with high accuracy, within microns. The touch-trigger probe mechanism evaluates dimensions to the required specifications and tolerances across all three axes – X, Y and Z. Full dimensional reports can be generated to demonstrate the stability and consistency of each product.Faro Arm

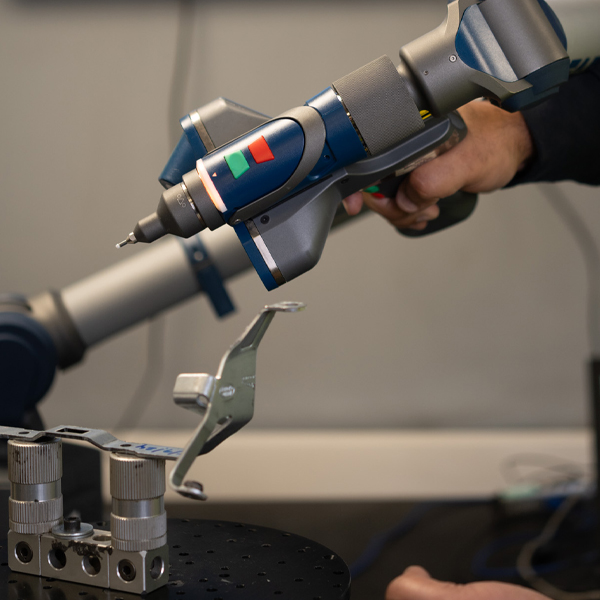

In addition to the CMM, we use a Faro Arm equipped with PolyWorks software. The Faro Arm features a non-contact scanning system that allows us to inspect products against master CAD models. Surfaces and features can be evaluated using a colour map output, providing a clear visual representation of dimensional variation. A key advantage of this system is its ability to assess surfaces that cannot be fully evaluated using traditional touch-probe measurement.Macro Weld Testing

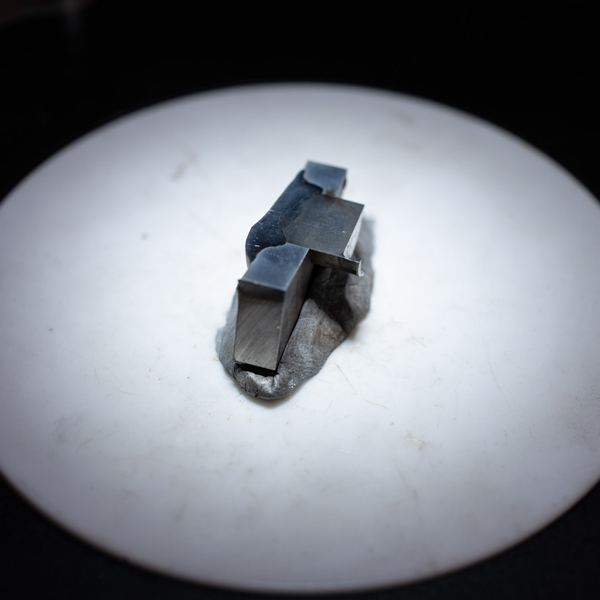

Weld condition and adhesion are assessed using our macro weld testing facility. Products can be cross-sectioned, polished and etched under controlled conditions. The resulting weld samples are then evaluated using our microscope and bespoke analysis software.

Contact Us

Talk to our team

Simply send us your queries and questions and a member of our

team will be in touch.

Visit us

If you would like to talk to us in person, you can find us at our manufacturing facility in West Bromwich, UK.